Environmental Chambers

Sharetree is a UK-based manufacturer of thermal and environmental chambers designed to meet the requirements of a wide range of industries. Established in 1972, we have decades of experience producing dependable systems that precisely control the climatic conditions inside our chambers, giving you repeatable and reliable results.

Our chambers:

- Deliver uniform and stable conditions throughout the internal volume.

- Contain efficient ambient air or compressor cooling systems.

- Optional liquid nitrogen cooling for lower temperatures and faster ramp rates (for ESS, HALT, etc.)

- Use high quality and readily available components to ensure long-term maintainability.

- Meet a wide range of test specifications:

- IEC 60068

- MIL-STD-810

- DEF-STD-00-35

- ETAG 004

- AGREE standards that combine thermal and vibration testing

- And many more...

Advantages

- Quality and reliability is built in through the use of high quality, readily available components, ensuring long term maintainability.

- Proven capability providing custom solutions including:

- ATEX rated

- Safe Handling of Products

- Highly Controlled Environments

- Integration with Legacy Test Systems

- Easy to use interface.

The Right Chamber For You

Our standard platforms cover a huge range of applications, from lab-sized chambers for drying pharmaceuticals to drive-in rooms for testing entire vehicles.

However, we don’t believe in selling off-the-shelf products exclusively. No matter what the requirements, we always speak to our customers first to understand their needs and work to agree the best solution for them.

This can include any number of customised features, for example:

- Introducing and controlling additional test parameters such as air velocity.

- Connecting power, monitoring equipment or gases through special ports in the chamber.

- Items under test that are tilted, rotated, or mounted on specialised frames.

- ATEX-rated internal spaces for testing potentially hazardous products.

Our in-house design engineers stand ready to adapt our standard chambers to meet your specific

requirements, or design completely bespoke systems when that is appropriate.

Excellent performance

Small footprint

Slimline range – designed for lower loads and general-purpose testing, simple to use and very reliable.

Desktop to 600ltr floor standing, with temperature ranges of +180°C to -70°C (+250°C to -100°C for LN2 versions), good humidity control from 10-100%RH and a host of options.

Prices from £11,700

High horizontal, laminar airflow for good thermal tracking

Cyclone range features powerful test chambers suited to more demanding applications.

From 300 to 1,500ltrs, capable of ramp rates from 2°C/min to 15°C/min under load and up to 60°C/min with LN2 cooling on the StressMaster2 ESS versions, which are ideal for HALT, HASS, etc.

Prices from £22,000

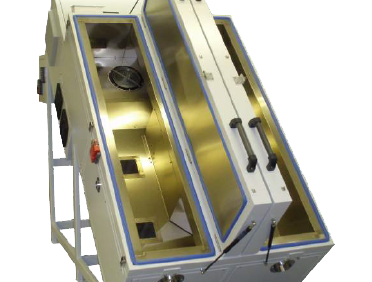

Tornado range – designed for large and/or heavy loads.

Easy to load and performs a wide range of thermal testing including industry specific specification (Auto, Aero, etc).

Standard models have sizes up to 5,250ltrs and loads up to 1T.

Custom sizes and features available.

Prices from £41,000

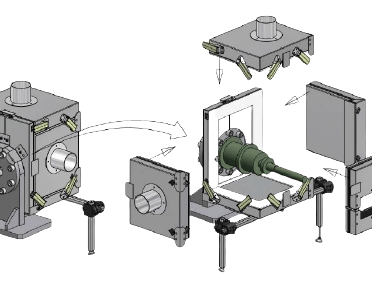

Chambers for long, thin loads

The RampMaster range was originally designed specifically for testing downhole tools, they have long, thin interiors and can be ordered with non-magnetic construction, L-shaped doors for easy loading and high-temperature (+250°C) compressor cooled versions.

Air-conditioning custom insulated enclosures

Often used in conjunction with custom enclosures, Slimline-ACU and Typhoon ranges offer a flexible way to deliver conditioned air to difficult test environments.

Temperature cycling and temperature humidity versions are available in sizes from small Slimline-ACUs to powerful Typhoons.

Create insulated enclosures around difficult test setups

For test environments unsuitable for standard ‘cubic’ chambers.

From single piece enclosures to proprietary, fully modular, clip-together solutions, there’s a custom enclosure for nearly any difficult test environment.

Large walk-in or drive-in chambers

The WIR/DIR range is available in standard modular and high-temperature, single-piece versions.

Ideal for creating controlled environments for large scale testing of sub-assemblies and complete products (vehicles, etc). Temperature cycling and temp/humidity versions available with a wide range of options. Sizes from 8,000 to 63,000ltrs.

For solutions needing something special

For projects unsuited to standard chambers either because of the product or test requirements.

We have designed and built a wide range of innovative solutions including: humidity drying, rotation and rolling systems, Hygrothermal solutions, high density Burn-In, non-magnetic, modular chambers, and many more.

Capable of meeting the demanding requirements such as EN14511

- Laminar airflow

- Airspeed controllable down to <0.5m/s over the product

- Highly stable temp and humidity control under load

- Responsive to defrost cycles, etc to recover condition quickly

- Integration with measurement/test systems